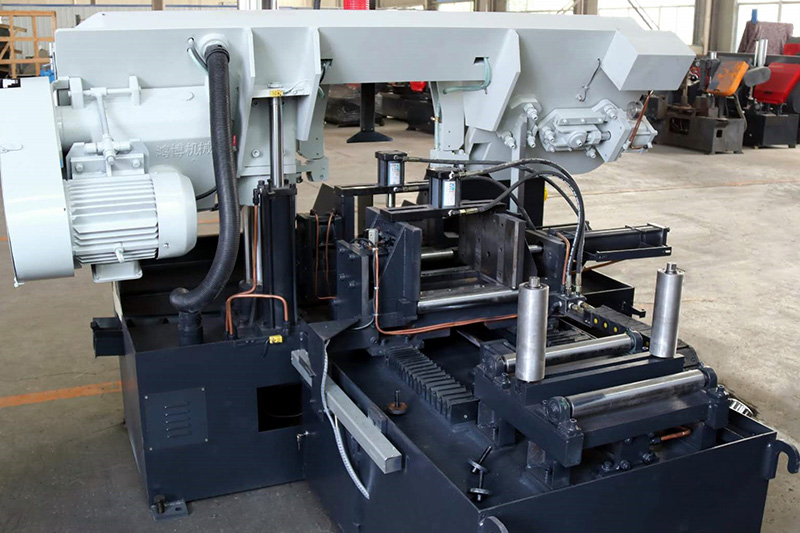

Intelligent High-speed Band Sawing Machine H-330

Specifications

| Model | H-330 | ||

| Sawing capability(mm) | Φ33mm | ||

| 330( W) x330( H) | |||

| Bundle cutting(mm) | Width | 330mm | |

| Height | 150mm | ||

| Motor power(kw) | Main motor | 4.0kw(4.07HP) | |

| Hydraulic pump motor | 1.5KW(2HP) | ||

| Coolant pump motor | 0.09KW(0.12HP) | ||

| Saw blade speed(m/min) | 20-80m/min(stepless speed regulation) | ||

| Saw blade size(mm) | 4300x41x1.3mm | ||

| Work piece clamping | Hydraulic | ||

| Saw blade tension | Hydraulic | ||

| Main drive | Worm | ||

| Material feeding type | Grating ruler control, linear guide | ||

| Feeding stroke(cutting length) mm | 500mm, exceed 500mm reciprocating feeding | ||

| Work table size(mm) | 670 | ||

| Over size (LxWxH)mm | 2180x2100x1600 | ||

| Net weight(kg) | 1600 | ||

Main features

● Automatic NC saw applicable to mass production and continuous cutting.

● Touch screen operation with built-in PLC system, fully automated, and allow the operator to program and store multiple cutting jobs including cut off lengths and number of cuts. After setting of cutting jobs, automatic feeding and sawing start.

● The double-column structure is of stable saw cutting and high precision.

● The work holding is hydraulic pressure with convenient operation.

● With "constant sawing force" as core principle, the intelligent sawing system monitors blade stress condition at real time and adjust feeding speed optimally. This system prolongs blade use life and improves sawing efficiency.

Details

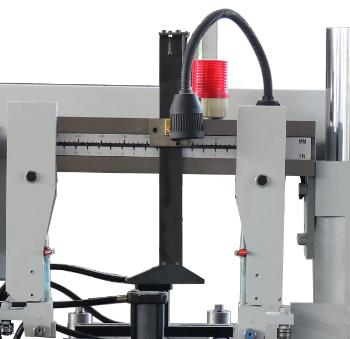

Control Panel

INOVANCE intelligent HMI and physical button combination design made for a convenient operation.

Chip Conveyor Device

Chip conveyor device: screw type chip conveyor will convey chips automatically to the chip stock box when machine is in operation.

Fast Drop Rod Water Outlet

Special fast drop rod water outlet design with improved water exit points: improve coolant effect and prolong blade life.

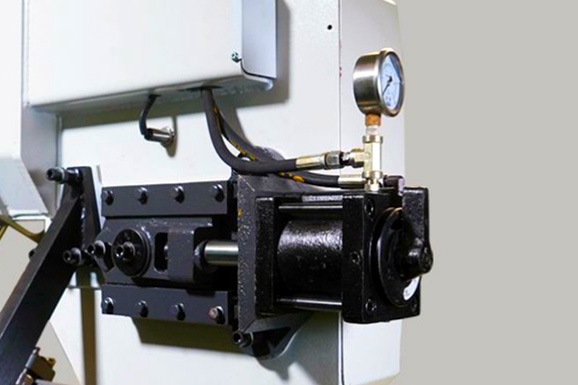

Blade Tension

Blade equipped with hydraulic tension device which moves the drive saw wheel to achieve the aimed blade tension and will loosen automatically after the machine is stopped.

Intelligent Sawing System

The intelligent sawing system is completed developed by JinFeng, with constant sawing force as core principle, the system monitors blade stress condition at real time and adjusts feeding speed optimally. This system prolongs blade use life and improves sawing efficiency, and can truly achieve the effect of high speed.

Hydraulic System

Adopt solenoid valve group produced by listed company, quality guaranteed, anti-jamming, and add two groups stacked unidirectional throttle valve. The valve base use aviation aluminum alloy, better heat dissipation and easier for maintenance.