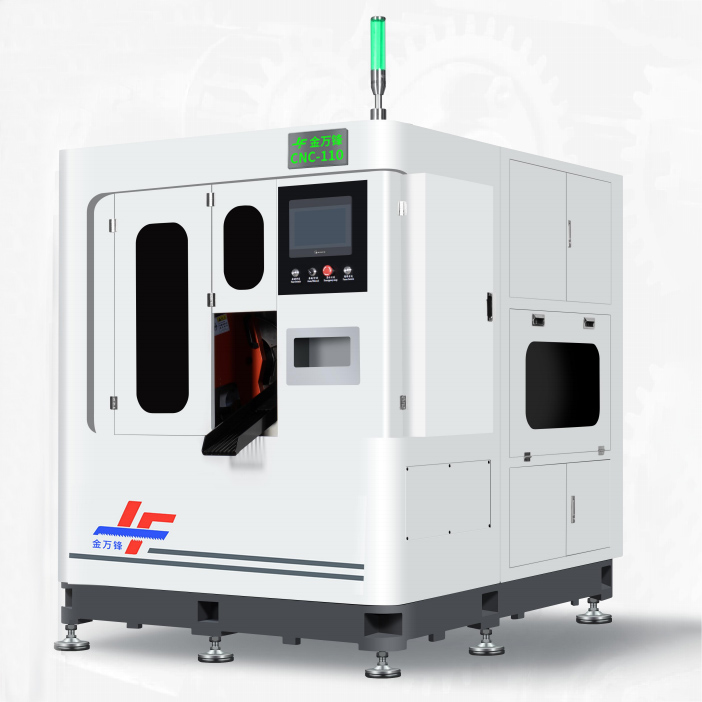

CNC120 High Speed Circular Saw Machine

Technical Parameter CNC120

| Cutting Capacity | ● 30~120mm ■ 30~100mm |

| Fixed feeding method | Servo motor+ball screw |

| Feeding clamp | Parallel hydraulic |

| End residue length | 75mm |

| Single feed cut length | 5~750mm |

| Use TCT superhard circular saw blades | φ360x2.6mm |

| Spindle speed | 30~160rpm |

| Spindle motor | 11KW |

| Saw blade debris removal device | Round wire brush |

| Gear gap compensation device | 5KG magnetic powder brake 5KG |

| Cut feed mode | Servo motor+ball screw+linear guide |

| Main clamp way | Hydraulic type/vertical and horizontal clamping of each group |

| Allow the length of material | 2000~9000mm |

| Supply mode | Hydraulic lifting |

| Pneumatic pressure | 4~6kg/cm²(55~85psi) |

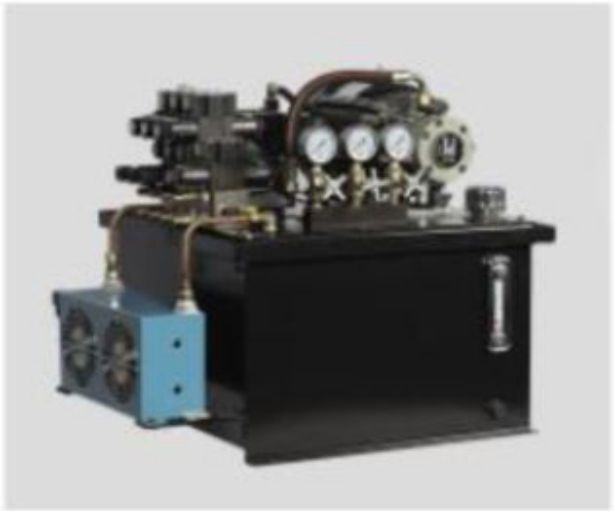

| Hydraulic device & configuration | |

| Self-lubrication system | Quantitative force to oil |

| Dispenser | Pneumatic reciprocating |

| Chip conveyor | Chain plate type |

| Spray cooling system | Oil mist bubrication spray devie |

| Work light | 50w water and dust proof light |

| Hydraulic drive motor | 3.75KW (4HP) / 4P |

| Hydraulic system rated pressure | 70kg/cm² (7Mpa) |

| Hydraulic oil capacity | 110 liters |

| Size | Machine+5M rack: 6600x3000x1700mm |

| Weight | 5500kg |

Feaures

a. Casting body, specially designed for precise cutting of pipe and bar.

b. TCT super hard saw blade and HSS high speed saw blade can be used.

C. Saw blade three-point clamping design reduces saw blade vibration to improved blade life.

d. The use of new design of the material to avoid feeding the workpiece friction with the nip surface, to ensure the accuracy of feeding.

e. One-button startup, conversational touch input, easy operation.

Standard Configuration

Taiwan TBI ball screw

Mitsubishi frequency gear box

Mitsubishi control system

Taiwan 7 YANG hydraulic station

Mitsubishi servo motor

WEINWIEW

Write your message here and send it to us