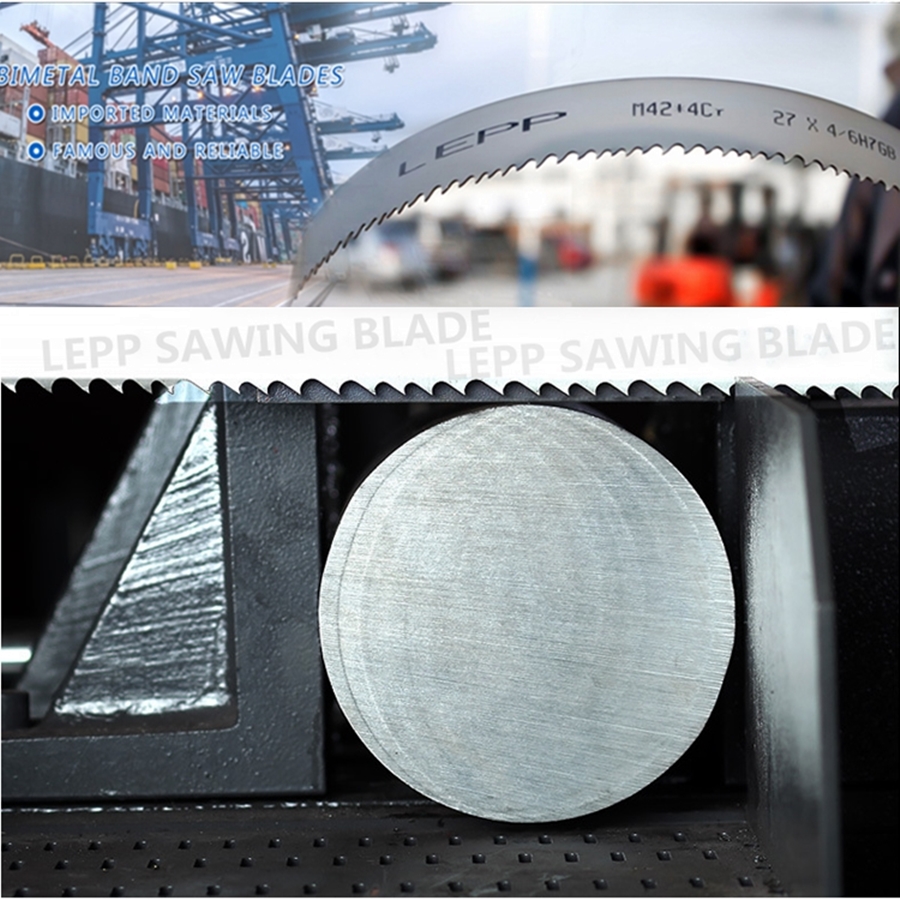

Bi Metal Band Saw Blade

Specifications

| Product Name | Professional Hss Bi-metal Band Saw Blade For Saw Blade Sharpening Machine |

| Material | M51/M42 |

| Specification | 27mm*0.9 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 34mm*1.1 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 41mm*1.3 1.4/2TPI 1/1.5TPI 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 54mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 67mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 80mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI |

| Material Cutting |

carbon steel/mold steel/Alloy steel/Stainless steel |

| Advantages | Materials feature m42 bi-metal bandsaw blade is a double metal structure: B318 backing, fatigue strength;M42 tooth material,8% cobalt content, tooth hardness HRC67-69The main advantage of bi-metal band saw blade is: 1. High wear resistance and high red hardness; 2.Serrated not easy to break; 3. Long service life. |

| Packages | the blades with the plastic cover and then 10 pcs into one carton/box |

| Min order | With the customers' requirements |

| Delivery time | 7 days after the advanced payment |

Bimetal Band Saw Blade

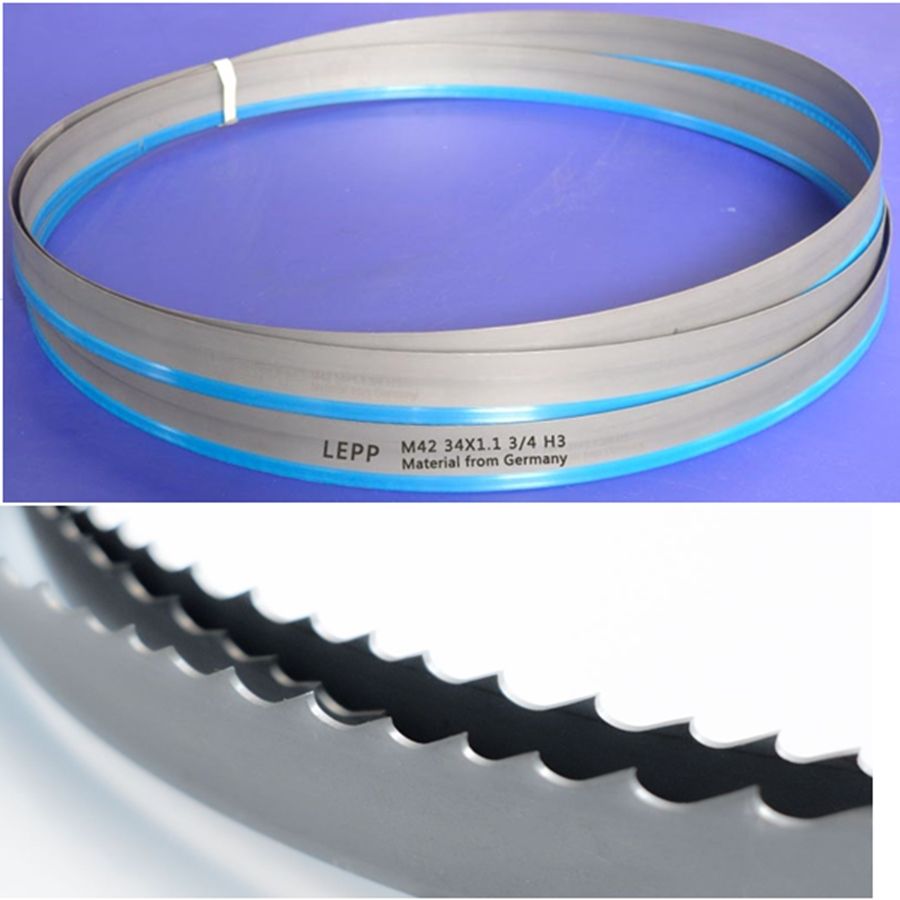

M42 Bimetal Band Saw Blade with Cobalt

This high-performance saw band is specially suitable for serial cutting of all types of metals. The teeth are made of alloyed high speed steel with 8% cobalt and 10% molybdenum.

Advantages:

★ 30-100% increase in cutting speed compared to tool steel band saw blades

★ up to 50% reduction in cutting time, resulting in higher productivity.

★ operating life 10 times that of tool steel bands increased cutting accuracy

★ These advantages result in more cost-efficient cutting operations both for one-time applications and serial production.

M51 Bimetal Band Saw Blade with Cobalt and Tungsten

This band saw blade is designed for use in heavy duty cutting applications. The cutting performance of the high speed steel teeth is greatly increased through alloying with cobalt tungsten. These alloying elements substantially increase heat resistance as well as fatigue resistance.

Advantages:

★ longer operating time.

★ increased cutting accuracy.

Allows cost-efficient cutting of materials with low maintainability such as stainless steel.

Product Details

Sawing machine operation points(effectively maintain the service life of the saw blades, the adjustment of sawing machine in very important):

1. Guide arm:

Adjusting the guiding arm as close as possible to the material.

2. Guide wheel:

Check the bearing to discover wearing and damage, in this way the guide wheel can effectively guide the saw blade.

3. Steel wire wheel:

Check the position of the steel wire wheel to ensure the chip can be effectively removed.