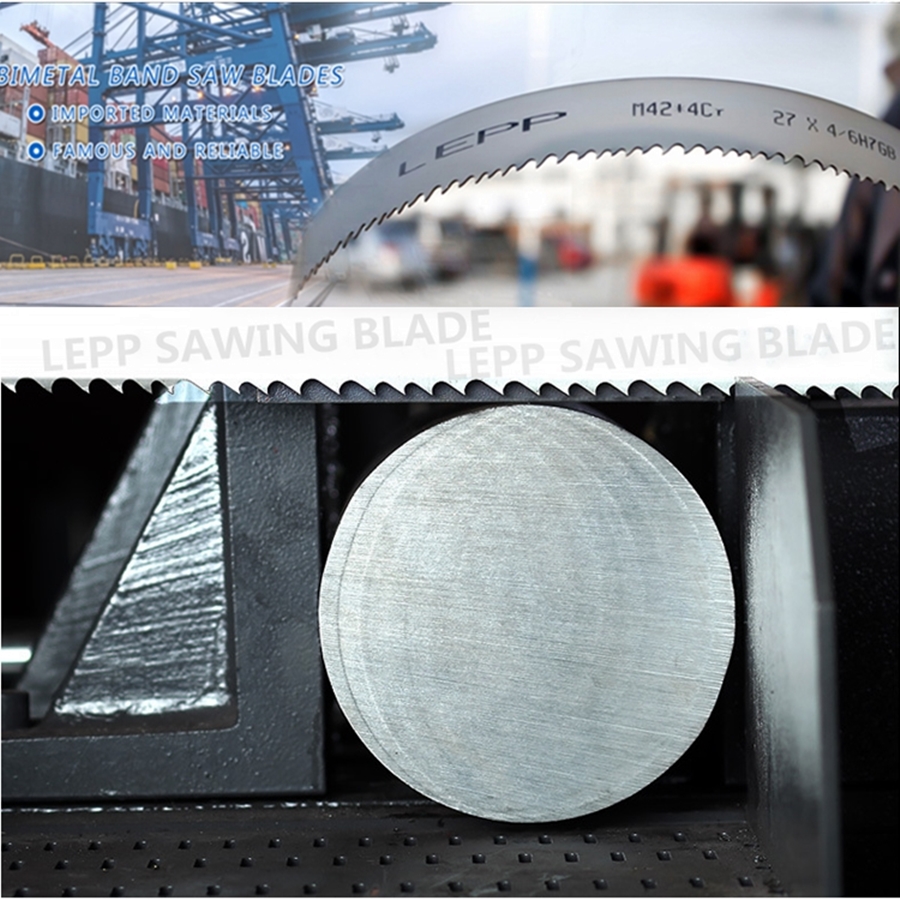

Band Saw Blade

Specifications

| Product Name | Professional Hss Bi-metal band saw blade for saw blade sharpening machine |

| Material | M42 / M51 |

| Specification | 27mm*0.9 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 34mm*1.1 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 41mm*1.3 1.4/2TPI 1/1.5TPI 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 54mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 67mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 80mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI |

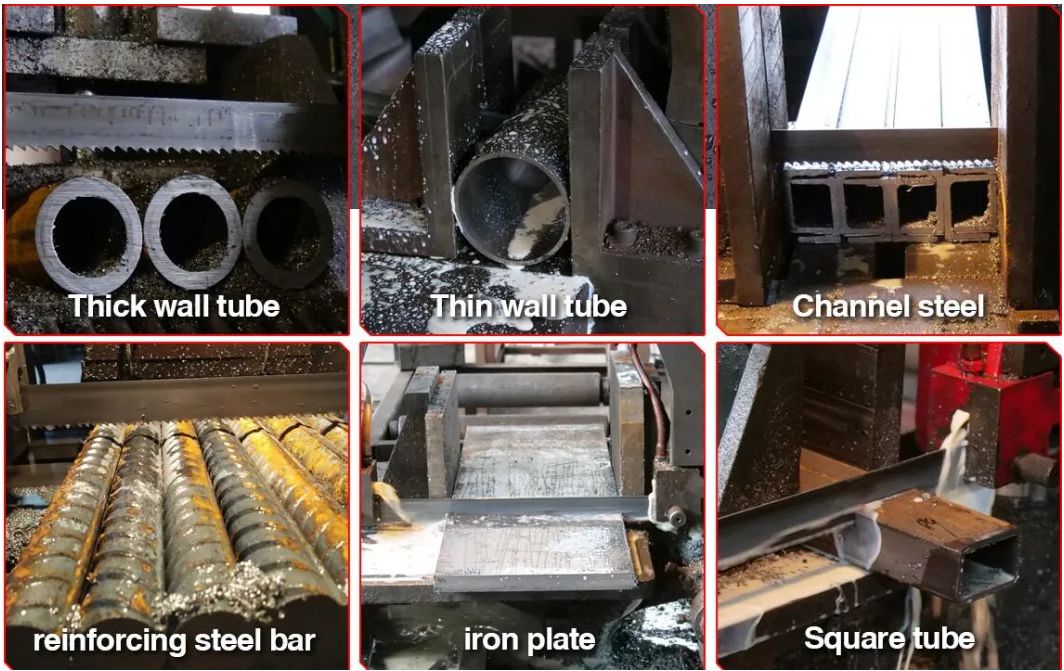

| Material Cutting | Carbon steel/mold steel/Alloy steel/Stainless steel |

| Advantages | Materials feature m42 bi-metal bandsaw blade is a double metal structure: B318 backing, fatigue strength; M42 tooth material, 8% cobalt content, tooth hardness HRC67-69.The main advantage of bi-metal band saw blade is: 1. High wear resistance and high red hardness; 2. Serrated not easy to break; 3. Long service life. |

| Packages | the blades with the plastic cover and then 10 pcs into one carton/box |

| Min order | With the customers' requirements |

| Delivery time | 7 days after the advanced payment |

Feaures

Two materials, high speed steel(HSS) for the teeth and alloyed tool steel as a backing material, are joined during the beam welding process. The specially developed backing material, alloyed with 4% chromium, has excellent mechanical properties under dynamic loading. This welding process results in an optimal combination of materials with respect to saw blade resistance to wear and fatigue.

◆ Resists heat, abrasion , and shock;

◆ Can be used in horizontal and vertical machines;

◆ Idea for contour and general purpose cutting;

◆ Alloy backer provides the fatigue resistance for long blade life;

◆ The high speed steel edge offers durable, tough cutting ability.

Write your message here and send it to us